We provide the best technology for draining waste water and sewage.

By providing a sewerage system for municipalities, sites and family houses, we process used water that is then returned to circulation. In this way we help maintain a clean environment.

Advantages of the PRESSKAN® pressure sewerage system

- Automatic operation and low sewerage charges.

- A closed system without leakage into groundwater.

- Low electricity consumption.

- A reliable system that has operated for over 30 years.

- Environmental protection.

- A Czech product, made by us.

- Spare parts availability.

How the Presskan pressure sewerage system works

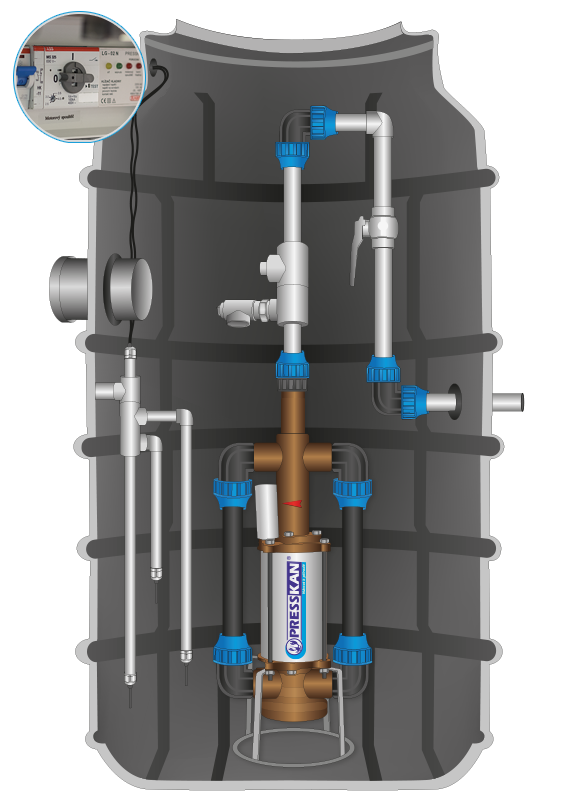

The basic PRESSKAN® pressure sewerage system unit is a pump shaft with a sludge pump, which is operated via a control panel.

Our technology consists of the following components:

- A PRESSKAN ® submersible sludge pump

- A non-return ball valve

- A ball valve

- Level sensors

- A PRESSKAN ®– THS control panel

- Sheathed power and control cables

- Discharge HDPE pipes and elbows

- A pump shaft (plastic, concrete)

- A gravity connector (optional)

The pump shaft and the technology is installed under the terrain level (with the exception of the control panel).

The whole system is controlled via the automatic control box mounted on a wall or in a separate stand. This box contains control lights that indicate the status of the pump.

The positive displacement pump is located in the pump shaft. This shaft collects waste water from the building. The pump is operated via the control panel and a level sensor. Once the level reaches the top sensor, the pump is switched on and the shaft content is pumped into the pipes. The pumped water is transported via the pipes to a waste water treatment plant. The pump automatically switches off once the level in the shaft drops.

Advantages of our technology

- NARROW EXCAVATIONS without the need for a gradient to a depth of 0.9 m – 1.2 m (non-freezing depth).

- LOW OPERATING COSTS guaranteed by the self-cleaning effect of the pressure pipe and low electricity consumption.

- WATERPROOF.

Hover over the selected number to view the description.

Most common use of our technology

- Pumping waste water to a pressure sewerage system.

- Pumping waste water to a gravity sewerage system – when the building is below the level of the main sewer system.

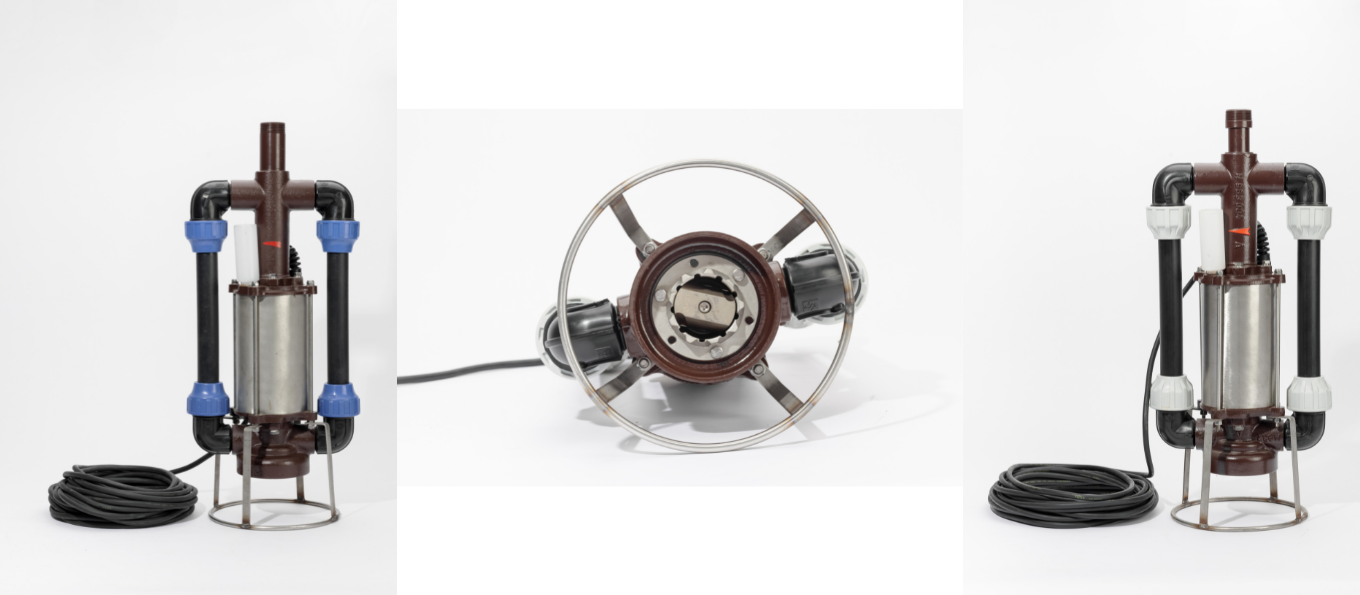

Pressure pump

The screw sludge pump is the heart of our technological solutions.

Its main function is to pump waste and sludge waters, and it works perfectly! Not even grass, straw or fruit and vegetable peels can stop it. It can easily handle solid particles with a grain size of up to 5 millimetres.

The robust build of the sludge pump and the quality materials used guarantee its high durability, making this pump suitable for operation even in more demanding conditions. The pumps are also equipped with a special cutting device that can handle objects that may accidentally appear in the pressure sewerage pumping sumps, for example textiles without artificial fibres. This means you avoid frequent cleaning and clogging and save time and money.

If a fault does occur, do not despair. The pump is easy to repair and easy to disassemble. We can provide you with any spare parts you may need.

The 1¼” NP–S pumps are made for voltage of 3 x 400 V or 230 V. Both versions are pressure-network compatible.

Applications

- Pumping waste water to a pressure sewerage system.

- Pumping waste water to a gravity sewerage system – when the building is below the level of the main sewerage system.

Control panel

The THS control panel is the brain behind our technology.

It powers, protects and controls the operation of our sludge pumps.

The control panel operates the pump and lets you know that everything is in order. You have an overview of the operation of the technology at all times.

The control panel can be supplied with:

- An operating hours counter that informs you how much water the pump has pumped.

- Acoustic signals in addition to visual signals to notify you of any defects.

- Remote transmission of operation status. This is a GSM module that can remotely inform you about the status of your pump.

- Remote control using a master system. We developed the ALFEUS smart pressure sewerage so that you can have the entire technology under control.

The control panel can be supplied in different voltage versions (400 V or 230 V). The control panel can operate one or multiple connected pumps.

Sump tank

The sump tank is the body of our technology.

This is where water from your entire household – your kitchen, toilet, bathroom and laundry – goes. The sump tank is made using so-called rotation forming of a monolithic structure. This means that it is made out of a single piece. There are no seams or joints on its surface, which prevents internal tension.

The shaft is supplied with:

- Rubber sealing sleeves to seal each millimetre.

- A lid to close the shaft. This ensures the shaft cannot be accidently opened and is protected against ingress of dust, sand, etc. The lid has a load-bearing capacity of up to 200 kg, so you can walk over it, e.g. when gardening.

Applications

- Walk-over variant – the polyethylene tank is placed under the surface and closed with a plastic lid. The pressure shaft is safely closed. The lid load-bearing capacity is 200 kg.

- Drive-over variant – the polyethylene tank is placed under the surface and so-called concrete distribution board is applied around it to evenly distribute excess weight. The shaft is safely closed with a concrete or cast iron lid with a load-bearing capacity of several tonnes. The drive-over variant can be used, for example, in front of a garage. Where maximum load-bearing capacity is required, e.g. for trucks, a reinforcing concrete filling is applied around the pressure shaft.

We manufacture tanks of various sizes and can design solutions for specific dimensions.

| Průměr 0,8 m, výška 2,0 m |

| Průměr 0,8 m, výška 2,3 m |

| Průměr 0,8 m, výška 2,5 m |

| Průměr 1,0 m, výška 2,0 m |

| Průměr 1,0 m, výška 2,3 m |

| Průměr 1,0 m, výška 2,5 m |